My sister (the other Shwin) is getting married. I volunteered to make her dress since I always wanted to try making one. It was a lot of fun to design with her and we are both so thrilled with the result. I thought I would post a bit about the process and info on where we got the supplies. We were able to make the whole dress for under $300 (including the muslins) granted the dress also took roughly 40 hours to make, it was a labor of love.

My sister had a few ideas of what she wanted in a dress and we searched high and low for a pattern since I wanted to work from a pattern to start with. I could have drafted one, sure, but I thought starting with a pattern would eliminate some of the work. However when we couldn’t find what we were looking for I started by mashing 2 patterns together, and then I used a third to perfect the fit we wanted.

For the dress her must haves:

- Mermaid fit

- Slim fitting with princess seams

- Elbow length sleeve

- Lace train

- Boatneck neckline

The patterns we found were the Vouge 1032 wedding dress it had the right fit and silhouette from the waist down, but not the top that she wanted. Then we found Vouge 9239 which had the princess seams and the neckline we wanted.

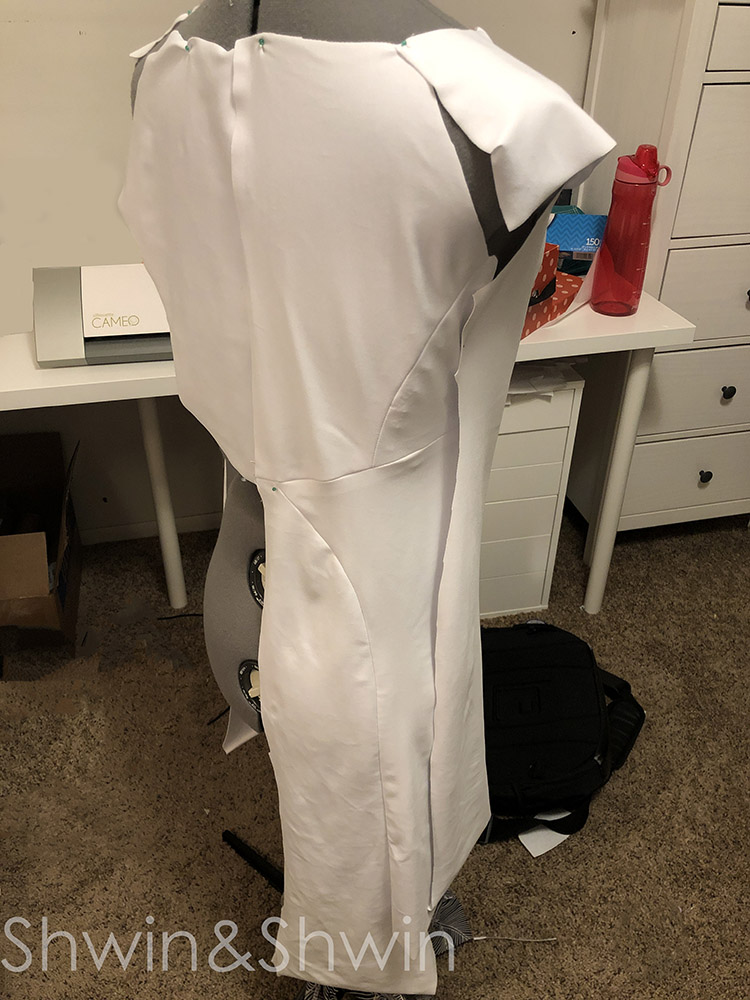

So the first thing I did was mash those two patterns together. I made sure they were both Vouge patterns so they would hopefully mash together well. I was able to use the waistline markings as a great place to mash them together. Another challenge if you will was that my sister decided she wanted her dress to be knit. Why? So it could fit like a glove (think body con dress) and she would still be able to move and be comfortable. Kind of a dream but the patterns were for woven fabrics and silks so it was a little tricky to swap it. I made 2 sizes smaller than she measured at. (also because these patterns are known for having what I feel is a lot of ease) So first things first was to make a muslin so we could see if the pattern mash and fit worked. Made from a cheap knit that was about the same stretch as we would use in the final.

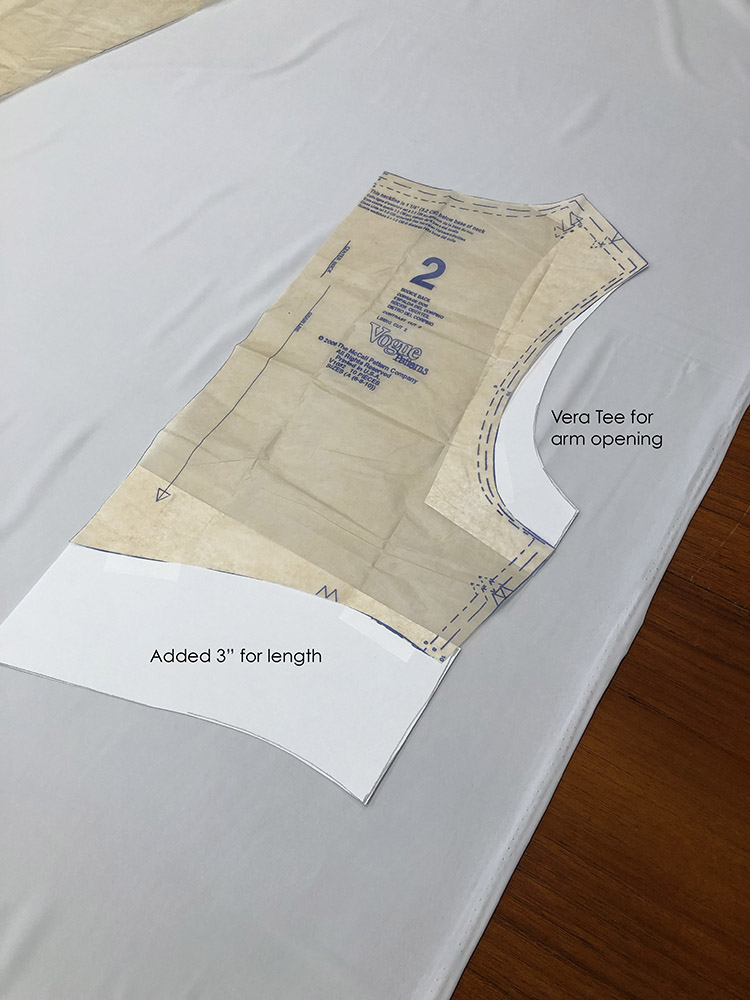

After the initial fit of the muslin we found we needed to add 3″ to length in the torso and the shoulder/sleeve/arm fit was terrible. The fit was awkward and weird so I switched to the Vera V-Neck I knew that shoulder and sleeve fit her really well and how we wanted for the dress so I mashed that into the pattern combo as well.

Mashing the pattern went something like this. The top center bodice of the 9239 dress attached to the front center skirt of the 1032 at the waistline marking. Then slashed for an added 3″ for her height. Then for the top I added the fit from the Vera but with an altered neckline so she would have the boatneck fit she wanted.

For the back, since I would have had to do a narrow back adjustment anyway I used the actual back piece of the 1032 dress adjusting for the length and altering the armhole for the Vera fit.

Then we were able to do a final fitting. The fit was great. I needed to let it out over the hip a bit and then take it in through the waist a bit, those alterations were easy and are what gives the dress the perfect custom fit.

Fabric sources:

The main dress was a heavy weight ponte from Cali Fabrics the fabric was a dream, smooth and pretty. A great weight and quality.

The lining was a thinner white spandex knit from Joanns

The lace also from Joanns had a lovely border I used along the hem of the dress and the pattern of the lace I used for the train. Then I also hand trimmed pieces of the lace for some accents on the body.

For the shoulders and back I added some lace (mainly to tie in the train) It would have been a TON of hand sewing so I used fabric glue to attach the hand trimmed lace pieces to the dress and then I hand stitched down a few sections.

To do the hem of the dress I sewed in some horse hair braid so the dress would drape nicely. Then after hand sewing the horse hair to the lining to complete the hem, I added the lace around the edge. Again I used the glue to help hold most of it in place.

Last little details, the buttons down the back that are decoration only were sewn on after the zipper was all installed, simply sewn on just to the side of the zipper.

So, end of the story is that the dress was a labor of love with MANY hours spent but not a lot of money. It was fun to make and seeing her in it on her special day makes it all worth it. So would you ever make a wedding dress?